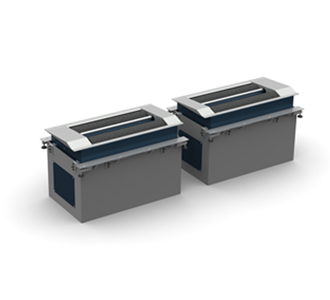

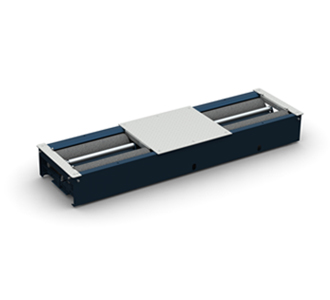

The RBT (Roller Brake Tester) on the market is divided into Split-type or Integrate-type. The Split-type Brake Tester is divided into two independent left and right brake benches, and the Integrate-type Brake Tester is integrated into a frame.

When faced with different sizes of RBT, customers will ask: What type do I need?

There are two main factors that determine the length of RBT: one is the length of the corundum rollers, and the other is the position of the motor.

The length of the corundum rollers is determined by the maximum and minimum wheel base of the vehicle that needs to be tested, in short, the larger the range of wheel base demand, the longer the required corundum rollers, and each country has different requirements (length and diameter) for the size of the corundum rollers, so we need to consider these two requirements comprehensively to determine the length of the roller, Jevol can provide any length of rollers customization service.

In addition, the position of the motor also affects the size of RBT. According to the connection between the corundum rollers and the motor, the brake testers on the market is generally divided into two types: one is side-mounted and the other is under-mounted. The side-mounted type is to design the motor on the side of the rollers, the advantage of this design is that it is convenient to maintain, in the regular maintenance and calibration, only need to remove the cover plate on both sides of the brake tester, the disadvantage is that the floor area is wide, the cover plate on the side unable to bear the weight of a passing vehicle.

The advantages and disadvantages of the under-mounted design are just the opposite of the side-mounted type, which makes the RBT more compact, but it is very troublesome to maintain it every time, and the entire RBT needs to be lifted out of the foundation pit when replacing accessories.

Both design methods will not affect the accuracy of the detection, customers only need to choose according to their actual situation.